Enhancing Efficiency and Sustainability Through Advanced Paper Bag Machine Automation

Release time:2025-05-24 Classification:Knowledge

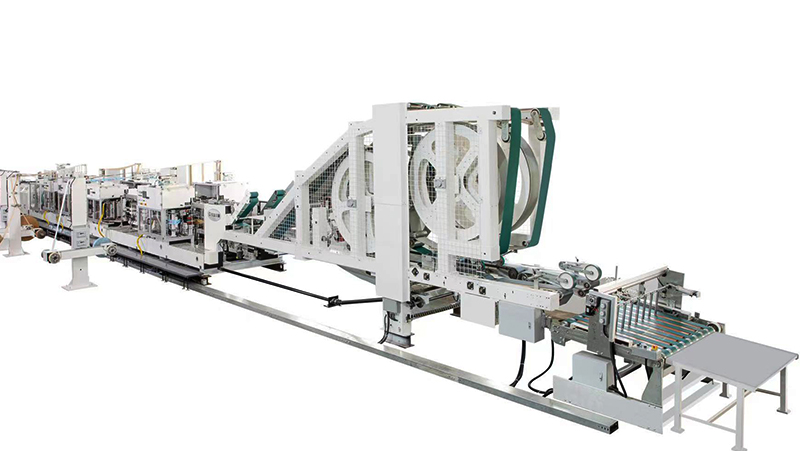

In the rapidly evolving packaging industry, automation has emerged as a cornerstone for improving productivity, reducing operational costs, and meeting growing environmental demands. Among the innovations driving this transformation, automated paper bag manufacturing systems stand out as a critical solution for businesses seeking to modernize their operations. This article explores the technological advancements in paper bag machine automation, its benefits, and how Yideng Machinery is leading the charge in delivering cutting-edge solutions tailored to contemporary manufacturing needs.

The Evolution of Paper Bag Manufacturing

Traditional paper bag production relied heavily on manual labor and semi-automated processes, which often resulted in inefficiencies, inconsistent product quality, and high labor costs. As consumer preferences shifted toward eco-friendly packaging and businesses faced pressure to scale production, the industry demanded smarter, faster, and more reliable solutions. Enter automation—a game-changer that has redefined every stage of paper bag manufacturing, from material handling to final packaging.

Key Features of Modern Automated Paper Bag Machines

Today’s automated paper bag machines integrate precision engineering with intelligent software to optimize performance. Key features include:

- High-Speed Production: Advanced servo motors and synchronized systems enable machines to produce thousands of bags per hour, significantly outpacing manual methods.

- Precision Cutting and Folding: Laser-guided sensors and programmable logic controllers (PLCs) ensure exact dimensions and consistent folds, minimizing material waste.

- Multi-Layer Handling: Automated systems seamlessly process multi-layered materials, including recycled paper and biodegradable laminates, to create durable, eco-friendly bags.

- Real-Time Quality Control: Integrated vision systems detect defects such as misprints or uneven seals, allowing immediate corrections and reducing rejection rates.

- Energy Efficiency: Smart power management systems reduce energy consumption by optimizing machine cycles and minimizing idle time.

Benefits of Automation for Manufacturers

Adopting automated paper bag machinery delivers tangible advantages:

- Cost Savings: Reduced labor dependency and lower error rates translate to long-term financial benefits.

- Scalability: Automated systems easily adapt to fluctuating订单 volumes, supporting business growth without requiring additional workforce.

- Sustainability: Precision material usage and compatibility with recycled inputs align with global sustainability goals.

- Competitive Edge: Faster turnaround times and superior product quality enhance customer satisfaction and market positioning.

Yideng Machinery: Pioneering Intelligent Automation Solutions

At Yideng Machinery, we specialize in designing and manufacturing state-of-the-art paper bag machines that combine reliability with innovation. Our engineers have spent decades refining automation technologies to address the unique challenges faced by packaging manufacturers. Here’s what sets our systems apart:

1. Customizable Workflow Integration

Our machines are built to integrate seamlessly into existing production lines. Whether a facility requires standalone units or fully connected smart factories, Yideng’s solutions offer modular designs that adapt to diverse operational needs.

2. User-Centric Interface

Understanding that ease of use is paramount, our systems feature intuitive touchscreen controls with multi-language support. Operators can quickly program bag dimensions, handle custom designs, and monitor real-time diagnostics without specialized training.

3. Robust After-Sales Support

Yideng Machinery is committed to ensuring uninterrupted production. Our global network of technical experts provides 24/7 remote assistance, on-site maintenance, and readily available spare parts to minimize downtime.

4. Future-Ready Technology

By incorporating IoT-enabled sensors and cloud-based data analytics, our machines empower manufacturers to predict maintenance needs, optimize workflows, and make data-driven decisions—key components of Industry 4.0.

Applications Across Industries

Automated paper bag machines cater to a wide range of sectors:

- Retail: Produce branded shopping bags with high-resolution printing capabilities.

- Food Packaging: Manufacture grease-resistant and breathable bags for baked goods or fresh produce.

- Industrial Use: Create heavy-duty bags for construction materials or agricultural products.

- Luxury Goods: Craft premium bags with embossing, foil stamping, and handle-attachment features.

The Road Ahead: Automation and Sustainability

As governments worldwide impose stricter regulations on single-use plastics, paper bags are poised to dominate the packaging landscape. However, meeting this demand sustainably requires continuous innovation. Yideng Machinery is at the forefront of developing energy-efficient systems that utilize renewable materials while maintaining high output speeds. Our R&D team is also exploring AI-driven optimization tools to further enhance machine learning and predictive maintenance capabilities.

Paper bag machine automation is no longer a luxury—it’s a necessity for manufacturers aiming to thrive in a competitive, environmentally conscious market. By investing in advanced automated systems, businesses can achieve unparalleled efficiency, reduce their carbon footprint, and meet evolving consumer expectations.

Yideng Machinery remains dedicated to empowering manufacturers with robust, scalable, and sustainable solutions. To learn how our automated paper bag machines can transform your production line, contact our team today for a personalized consultation. Together, let’s build a smarter, greener future for packaging.