About

Company Profile

Suzhou Yideng Machinery Company was established in 2001, focusing on the research, development, and manufacturing of equipment and production lines required for paper valve bags. The company primarily serves industries such as construction materials, chemicals, and food packaging.

Company History

At the beginning, the company mainly imported second-hand paper valve bag production lines from Europe and the United States for refurbishment and upgrading services. After 20 years of technical research and experience accumulation, in 2020, we developed the paper valve bag bottomer machine with independent intellectual property rights in China, with a production speed of 200 bags per minute and a design service life of 20 years.

In 2021, we developed the Valve Bag Tuber Machine with a maximum production speed of 300 tubes per minute. We have established close ties with internationally renowned technical teams and have frequently visited Europe to stay updated on the latest industry technologies, fully understanding that innovation is limitless.

In 2023, we launched the next-generation Tuber Machine, with a speed of 450 tubes per minute.

In 2024, we developed an innovative Bottomer Machine with a production speed of 300 bags per minute, integrated with a conveyor system for fully automated production. This advancement made us one of the few companies in the world capable of providing complete integrated production lines.

We welcome more valve bag factories to contact us and share their requirements and suggestions. We are committed to providing innovative solutions to meet those needs and offering high-quality, cost-effective automated production lines.

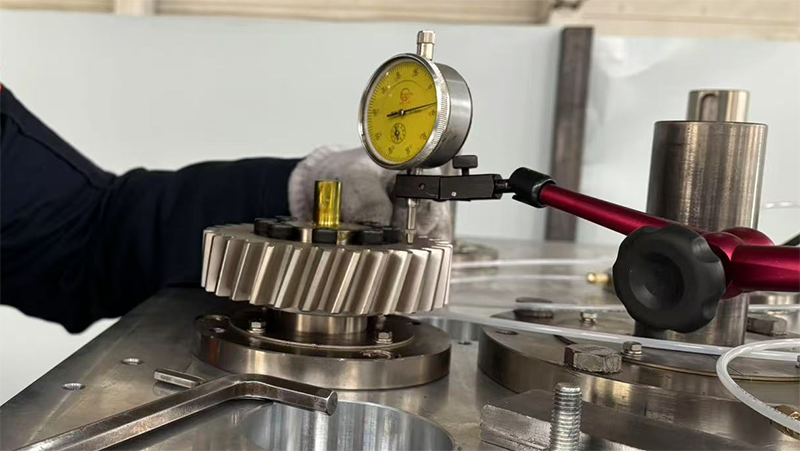

Currently, our factory covers an area of 6,000 m². We understand the importance of precision in parts, as it affects the frequency of maintenance and service life of the entire production line. Therefore, we are equipped with numerous large-scale machining equipment, including 60 large CNC machining centers, ensuring high precision with all parts produced to H6 accuracy standards. Additionally, we have high-precision CNC gear hobbing machines, and our gears are made from special steel and undergo 6 heat treatment processes, ensuring high precision and low noise.

Services

- 24/7 Response Service

We provide a 24/7 response service, with a dedicated WeChat group for each customer. The group includes our design engineers, installation and commissioning engineers, electrical automation engineers, and warehouse shipping personnel. Customers can easily reach out in the group for immediate responses to any inquiries or assistance. - Pre-shipment Training

Before equipment shipment, we invite the customer’s engineers to our factory for two weeks of commissioning training. - On-Site Installation and Commissioning Support

We will dispatch four engineers to assist with the installation and commissioning of equipment at the customer’s factory. - Lifetime Spare Parts Service

We commit to providing lifetime spare parts at cost price. - Remote and On-Site Support

If customers encounter any issues, they can contact us via email, phone, or video. We will offer remote service or on-site support as needed. - Spare Parts Inventory

We maintain an inventory of spare parts to ensure quick response to customer needs.