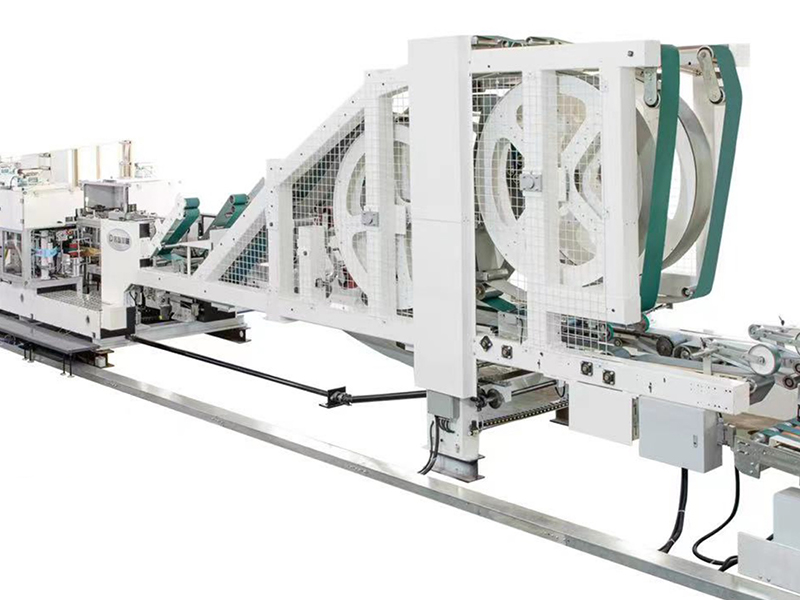

Chemical Paper Bag Machine

Chemical Paper Bag Production Line

Multi-wall paper bag machine suited to make valve type and open-mouth sacks for packaging chemical powder and granular materials

The chemical paper bag production line consists of the tuber machine YD-5875 and the bottomer machine YD-2825, designed for packaging powdered or granular solid materials such as carbon black, titanium dioxide, calcium chloride, magnesium chloride, and polyethylene chloride. Chemical valve bags are known for improving packaging efficiency, ease of transportation, strength, and low damage rates.

Additionally, we offer equipment that can be customized to match your specific production volume needs, providing machines with appropriate speeds to better meet customer requirements. We also offer complete factory solutions, including auxiliary equipment such as overhead cranes, forklifts, and hydraulic balers.

Get in touch with us today to discuss a customized chemical bag production solution tailored to your plant’s needs.

Tuber Machine YD-5875

- Tube length: 410-1650mm

- Max. speed: 450 tubes/min

- Tube width: 300-750mm

Bottomer Machine YD-2825

- External reinforcement patch length (optional): 200-550mm

- Max. speed: 300 bags/min

- Bottom width: 90-250mm

- Bag width: 300-720mm

- Bag length: 410-1450mm

- Center distance: 200-1350mm

- First valve sheet length (optional): 90-270mm

- Second valve sheet length (optional): 90-270mm

- Internal reinforcement patch length (optional): 200-450mm

Features

Automatic Sealing Equipment

The valve bag production line typically includes automatic sealing equipment, ensuring the valve is tightly sealed to prevent material leakage and reduce manual intervention.

High Production Speed

The production speed can reach up to 450 bags/min, handling large-scale packaging tasks and meeting high-volume production demands.

Precise Weight Control

The weight of the bags is accurately controlled, ensuring each bag contains the correct amount of material, preventing over or under-filling.

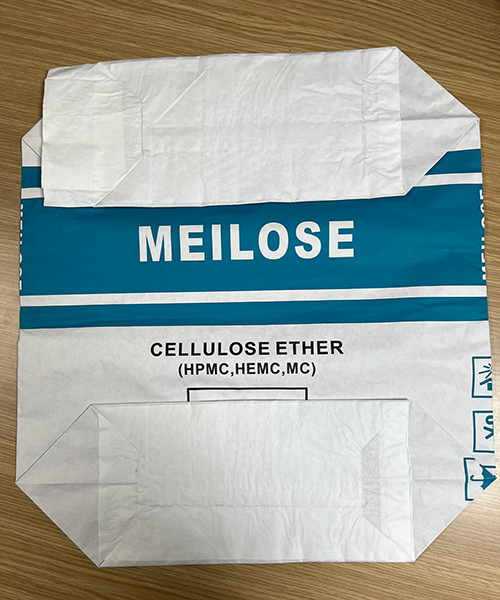

Samples of Valve Bag