Revolutionizing Packaging Standards: The Role of AI in Modern Paper Bag Quality Control

Release time:2025-05-15 Classification:Knowledge

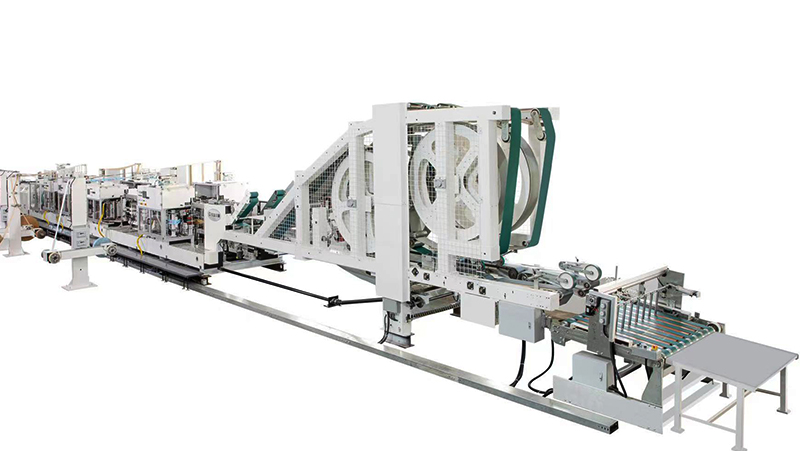

The manufacturing and packaging industries are undergoing a transformative shift with the integration of advanced technologies. Among these innovations, AI-powered quality control systems have emerged as a game-changer, particularly in the production of paper bags. By leveraging artificial intelligence, manufacturers can now ensure unparalleled precision, efficiency, and consistency in detecting defects, optimizing workflows, and maintaining compliance with environmental and safety standards.

The Challenge of Traditional Quality Control

Traditional quality control methods for paper bags often rely on manual inspections or semi-automated systems. These approaches are inherently limited by human error, fatigue, and the inability to process large volumes of data in real time. Minor defects—such as uneven seams, incorrect dimensions, or inconsistent print patterns—can lead to product recalls, wasted resources, and reputational damage. Furthermore, the growing demand for sustainable packaging solutions necessitates stricter adherence to quality benchmarks, as even minor flaws can compromise the durability and reusability of paper bags.

How AI-Powered Systems Transform the Process

AI-driven quality control systems address these challenges through a combination of computer vision, machine learning algorithms, and high-speed data processing. Here’s how the technology works:

- Computer Vision for Defect Detection

High-resolution cameras capture real-time images of paper bags at various stages of production. AI algorithms analyze these images to identify deviations from predefined specifications, such as tears, misaligned handles, or ink smudges. Unlike human inspectors, AI systems can detect submillimeter defects with 99.9% accuracy, even at high production speeds. - Machine Learning for Adaptive Learning

Over time, machine learning models improve their defect recognition capabilities by analyzing historical data. For instance, if a recurring issue like weak adhesive bonds is detected, the system flags it and adjusts inspection parameters to prioritize similar defects in subsequent batches. This adaptive learning minimizes false positives and ensures continuous process optimization. - Predictive Analytics for Proactive Maintenance

AI systems monitor equipment performance and predict potential malfunctions before they disrupt production. By analyzing vibration patterns, temperature fluctuations, or wear-and-tear metrics, the technology alerts technicians to address issues during scheduled downtime, reducing unplanned interruptions. - Sustainability and Waste Reduction

By catching defects early, AI-powered systems significantly reduce material waste. For example, identifying a misprinted design before mass production prevents thousands of non-compliant bags from entering the market. This aligns with global sustainability goals by conserving raw materials and lowering carbon footprints.

Key Benefits of AI-Driven Quality Assurance

- Enhanced Accuracy: Eliminates human error and ensures consistent adherence to quality standards.

- Cost Efficiency: Reduces waste, rework, and recall-related expenses.

- Scalability: Adapts seamlessly to high-volume production environments.

- Regulatory Compliance: Automatically verifies compliance with safety, durability, and eco-labeling requirements.

- Real-Time Reporting: Generates actionable insights for stakeholders, enabling data-driven decision-making.

Case Study: Implementing AI in Paper Bag Manufacturing

A leading manufacturer recently integrated an AI-powered quality control system into its production line. Within six months, the company reported a 40% reduction in defect rates and a 25% decrease in material waste. The system’s ability to analyze 5,000 bags per hour—compared to 200 bags inspected manually—allowed the facility to reallocate human resources to higher-value tasks, such as process optimization and R&D.

Future Trends and Industry Outlook

As AI technology evolves, its applications in paper bag quality control will expand. Emerging advancements include:

- 3D Imaging: Detects structural weaknesses in complex bag designs.

- IoT Integration: Synchronizes AI systems with IoT-enabled machinery for end-to-end process automation.

- Blockchain Traceability: Combines AI quality data with blockchain to create immutable records for supply chain transparency.

AI-powered quality control is redefining the standards of paper bag manufacturing. By combining precision, adaptability, and sustainability, this technology not only addresses current industry challenges but also paves the way for smarter, greener packaging solutions. As adoption grows, manufacturers that embrace AI-driven systems will gain a competitive edge, delivering superior products while advancing global sustainability initiatives.

The fusion of artificial intelligence and traditional manufacturing processes marks a pivotal step toward a future where quality, efficiency, and environmental responsibility coexist seamlessly.