Revolutionizing Packaging Efficiency: The Advanced Multi-Language Interface Bag Machine

Release time:2025-05-14 Classification:Knowledge

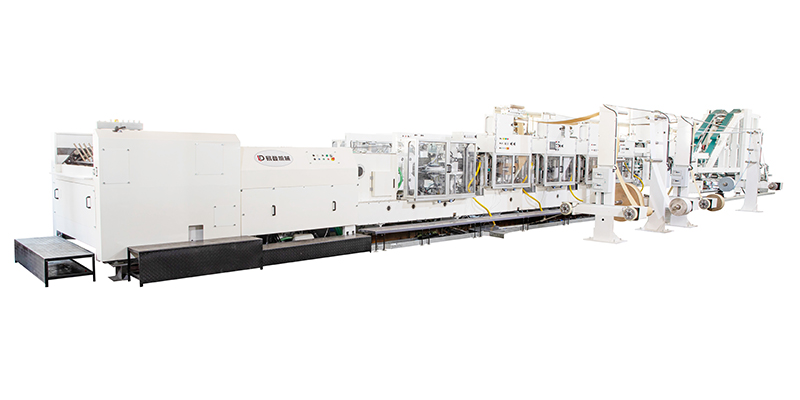

The packaging industry continues to evolve with innovations that prioritize operational efficiency, user adaptability, and cross-functional compatibility. Among these advancements, the Multi-Language Interface Bag Machine stands out as a transformative solution designed to streamline production workflows while addressing the challenges of globalized manufacturing environments. This article explores the technical features, operational benefits, and industry-wide applications of this cutting-edge equipment, emphasizing its role in modernizing packaging processes.

Technical Overview

The Multi-Language Interface Bag Machine integrates state-of-the-art automation with an intuitive user interface (UI) capable of supporting multiple languages. This feature eliminates language barriers for operators, enabling seamless deployment across diverse regions without compromising productivity. The machine’s core architecture includes:

- Adaptive Control System: A programmable logic controller (PLC) that dynamically adjusts settings based on material type, bag dimensions, and production speed.

- Multi-Language HMI: A touchscreen interface offering language options such as English, Spanish, Mandarin, French, and German, ensuring accessibility for international teams.

- Precision Drive Mechanisms: Servo motors and sensors that maintain accuracy in bag forming, filling, and sealing, even at high speeds.

Operational Advantages

- Enhanced User Accessibility

The multi-language interface reduces training time and minimizes errors by providing clear, localized instructions. Operators can swiftly switch between languages, ensuring compliance with regional safety protocols and operational guidelines. - Increased Production Flexibility

Designed for versatility, the machine accommodates a wide range of materials, including polyethylene, woven polypropylene, and biodegradable films. Its modular design allows rapid reconfiguration for different bag styles—stand-up pouches, gusseted bags, or flat sacks—without downtime. - Energy and Resource Efficiency

Advanced algorithms optimize material usage, reducing waste by up to 15%. Simultaneously, the machine’s low-power components and intelligent idle mode cut energy consumption by 20% compared to conventional models. - Data-Driven Performance Monitoring

Integrated IoT connectivity enables real-time tracking of production metrics, such as output rates, defect counts, and maintenance alerts. This data is accessible via the multi-language dashboard, empowering managers to make informed decisions.

Industry Applications

The Multi-Language Interface Bag Machine caters to sectors requiring high-volume, precision packaging:

- Food and Beverage: Ensures hygienic packaging for dry goods, liquids, and frozen products, with compliance to international food safety standards.

- Pharmaceuticals: Supports tamper-evident and child-resistant packaging formats, critical for medical supplies and over-the-counter drugs.

- Chemicals and Agriculture: Handles corrosive or granular materials safely, with customizable sealing options for moisture-sensitive products.

Technical Specifications

- Speed: Up to 120 bags per minute (dependent on bag size and material).

- Bag Dimensions: Adjustable within 50–500 mm (width) and 100–800 mm (length).

- Power Supply: 380–480 V, 3-phase, 50/60 Hz.

- Compatibility: Works with pre-printed rolls, inline printing systems, and RFID tagging modules.

Future-Proofing Packaging Operations

As industries expand into global markets, the demand for equipment that bridges linguistic and technical gaps grows exponentially. The Multi-Language Interface Bag Machine not only meets these needs but also incorporates scalability for emerging technologies. Future updates may include AI-driven predictive maintenance, augmented reality (AR) troubleshooting guides, and expanded language libraries to support lesser-spoken dialects.

The Multi-Language Interface Bag Machine represents a paradigm shift in packaging technology, combining user-centric design with industrial robustness. By eliminating language-based operational hurdles and enhancing adaptability, it empowers manufacturers to achieve higher efficiency, reduce costs, and maintain competitiveness in a rapidly globalizing market. As automation and smart manufacturing trends accelerate, this innovation positions itself as an indispensable asset for forward-thinking production facilities worldwide.