Innovative Integration of Coding Technology in Modern Paper Bag Manufacturing: Enhancing Efficiency and Traceability

Release time:2025-05-12 Classification:Knowledge

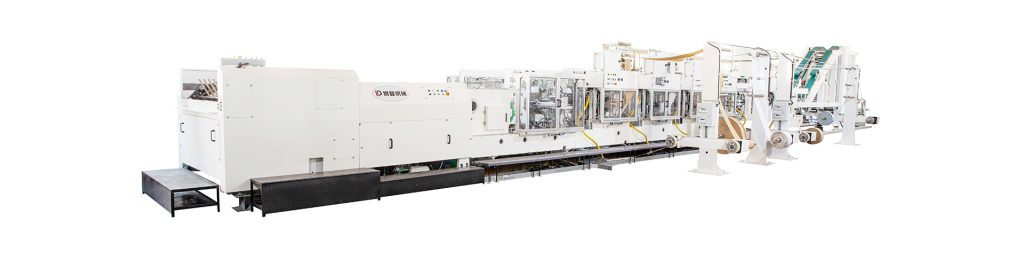

The evolution of packaging machinery has reached a new milestone with the development of the paper bag machine with coding function. This advanced equipment combines traditional paper bag production capabilities with cutting-edge coding technology, revolutionizing operational workflows, product traceability, and customization in the packaging industry. Designed to meet the growing demand for smart and sustainable solutions, this machine represents a significant leap forward in manufacturing precision and adaptability.

Key Features and Technological Advancements

- Integrated Coding System

The paper bag machine with coding function seamlessly incorporates high-resolution inkjet or laser coding modules directly into the production line. This allows for real-time printing of variable data—such as batch numbers, QR codes, expiration dates, or branding elements—onto paper bags during the forming process. The coding unit supports multiple languages, fonts, and graphics, ensuring compliance with global regulatory standards and enhancing brand visibility. - Precision and Speed Synchronization

Advanced servo-driven mechanisms ensure synchronization between the bag-forming and coding processes. This eliminates misalignment risks and maintains high-speed production (up to 120 bags per minute, depending on specifications) without compromising print quality. Adaptive sensors detect material thickness and adjust coding parameters automatically, guaranteeing legibility across diverse paper grades. - Smart Data Management

Equipped with IoT-ready interfaces, the machine enables centralized control of coding content via user-friendly software. Operators can upload designs, modify templates, or input dynamic data (e.g., sequential numbering) through a touchscreen interface. Production logs, including coded information and machine performance metrics, are stored for traceability audits and process optimization.

Applications and Industry Benefits

- Retail and Food Packaging: Enables compliance with food safety regulations by printing traceable batch codes and nutritional labels directly onto paper bags.

- Pharmaceuticals: Supports anti-counterfeiting measures through unique serialization and tamper-evident coding.

- E-commerce: Facilitates custom-branded packaging with on-demand printing of logos, promotional codes, or personalized messages.

Sustainability and Cost Efficiency

By integrating coding into a single automated system, the machine reduces material waste caused by pre-printed packaging inventory. Its energy-efficient design and use of eco-friendly, fast-drying inks align with circular economy principles, minimizing environmental impact while lowering long-term operational costs.

The paper bag machine with coding function redefines packaging automation by merging production agility with intelligent data integration. Its ability to deliver customizable, traceable, and eco-conscious solutions positions it as an indispensable asset for manufacturers aiming to thrive in an increasingly competitive and regulation-driven market. As industries prioritize sustainability and digital transformation, this innovation sets a new benchmark for smart packaging systems.