Precision Paper Bag Cutting Machines: Key Features, Advantages, and Industrial Applications

Release time:2025-05-10 Classification:Knowledge

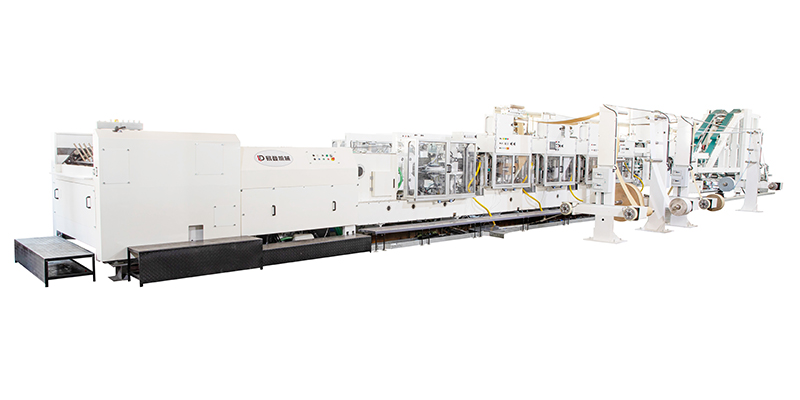

Precision paper bag cutting machines are advanced industrial equipment designed to streamline the production of paper bags with unmatched accuracy and efficiency. These machines cater to manufacturers seeking high-volume output, consistent quality, and minimal material waste. Below, we explore their core functionalities, benefits, and applications across industries.

Core Features of Precision Paper Bag Cutting Machines

- High-Accuracy Cutting Mechanism

Equipped with laser-guided or servo-driven systems, these machines ensure exact measurements for paper bag dimensions, reducing errors and material waste. Adjustable settings accommodate diverse sizes and styles, from flat-bottom bags to gusseted designs. - Automated Operation

Integrated automation minimizes manual intervention. Features like automatic feeding, alignment, and stacking boost productivity while maintaining uniformity across batches. - Material Compatibility

Engineered to handle various paper types—including kraft, recycled, and laminated paper—these machines adapt to different thicknesses and textures without compromising cutting precision. - User-Friendly Interface

Intuitive touchscreen controls and programmable settings simplify operation, allowing operators to switch between designs swiftly. - Durability and Safety

Constructed with robust materials, precision cutting machines withstand continuous use. Safety mechanisms, such as emergency stops and blade guards, ensure operator protection.

Advantages for Manufacturers

- Enhanced Efficiency: Rapid cutting speeds and automation reduce production cycles, enabling large-scale output.

- Cost Savings: Precision cutting minimizes material waste, lowering raw material expenses.

- Consistent Quality: Uniform cuts ensure every bag meets specifications, enhancing brand reliability.

- Scalability: Flexible configurations support custom orders and evolving production demands.

Industrial Applications

Precision paper bag cutting machines serve industries requiring high-quality packaging solutions:

- Retail: Produce branded shopping bags with crisp edges and clean finishes.

- Food Packaging: Create grease-resistant or laminated bags for takeout and grocery items.

- E-Commerce: Generate durable shipping bags optimized for logistics.

- Eco-Conscious Brands: Support sustainable practices by efficiently processing recyclable or biodegradable materials.

Choosing the Right Machine

When selecting a precision paper bag cutting machine, evaluate:

- Production capacity (speed and volume).

- Compatibility with existing workflows.

- Customization options for unique designs.

- Post-purchase support, including maintenance and training.

This equipment represents a critical investment for paper bag manufacturers aiming to optimize output quality and operational efficiency. By integrating advanced technology with user-centric design, precision paper bag cutting machines empower businesses to meet modern market demands while reducing environmental impact.