The Ultimate Guide to Heat Sealing Paper Bag Equipment: Benefits, Applications, and Key Features

Release time:2025-05-10 Classification:Knowledge

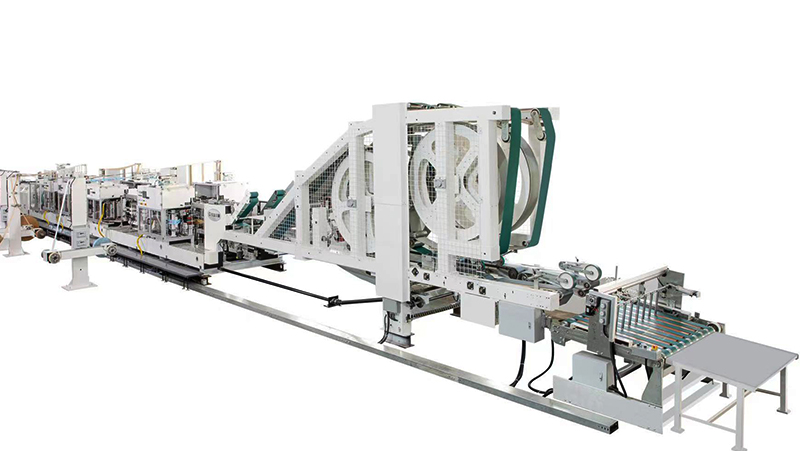

Heat sealing paper bag equipment is an essential industrial solution for businesses seeking efficient, sustainable, and cost-effective packaging. This technology enables the production of durable, leak-resistant paper bags with airtight seals, making it ideal for industries ranging from food packaging to retail. Below, we explore the fundamentals of heat sealing paper bag machinery, its advantages, and critical considerations for selecting the right equipment.

What Is Heat Sealing Paper Bag Equipment?

Heat sealing paper bag equipment refers to machinery designed to manufacture paper bags using heat-activated adhesives or films. The process involves applying controlled heat and pressure to bond layers of paper, creating a secure and tamper-evident seal. This method ensures bags maintain structural integrity while meeting hygiene and sustainability standards.

Key Advantages of Heat Sealing Technology

- Eco-Friendly Packaging: Compatible with recyclable and biodegradable materials, heat-sealed paper bags align with global sustainability initiatives.

- Enhanced Durability: Heat-sealed seams resist moisture, grease, and tearing, extending product shelf life and reducing waste.

- High-Speed Production: Automated systems enable rapid bag formation, boosting output for large-scale operations.

- Customization: Equipment supports variable bag sizes, shapes, and printing designs, catering to diverse branding needs.

Applications Across Industries

- Food & Beverage: Ideal for packaging dry goods, snacks, and frozen items.

- Retail: Used for branded shopping bags, luxury packaging, and reusable totes.

- Medical & Pharmaceutical: Ensures sterile packaging for medical supplies.

- Agriculture: Suitable for seeds, fertilizers, and organic products.

Critical Components of Heat Sealing Machinery

- Heating Elements: Precision-controlled heaters ensure consistent seal quality.

- Conveyor Systems: Automated feeding and alignment streamline production.

- Pressure Rollers: Apply uniform force to activate adhesives without damaging paper.

- Cooling Stations: Stabilize seals post-heating to prevent deformation.

How to Choose the Right Equipment

- Production Volume: Opt for semi-automatic or fully automated models based on output requirements.

- Material Compatibility: Verify machinery supports your paper type (e.g., coated, uncoated, or laminated).

- Energy Efficiency: Prioritize systems with low power consumption and quick heat-up times.

- Ease of Maintenance: Look for modular designs and accessible components to minimize downtime.

Maintenance Best Practices

- Regularly clean heating elements to prevent adhesive buildup.

- Inspect seals for consistency and recalibrate temperature settings as needed.

- Lubricate moving parts to ensure smooth operation.

Heat sealing paper bag equipment is a transformative investment for businesses prioritizing efficiency, sustainability, and product protection. By understanding its capabilities and selecting machinery tailored to operational needs, manufacturers can optimize packaging workflows while reducing environmental impact. As demand for eco-conscious packaging grows, heat sealing technology remains a cornerstone of modern industrial solutions.