High-Efficiency Paper Bag Making Machines: Key Features, Benefits, and Applications

Release time:2025-05-01 Classification:Knowledge

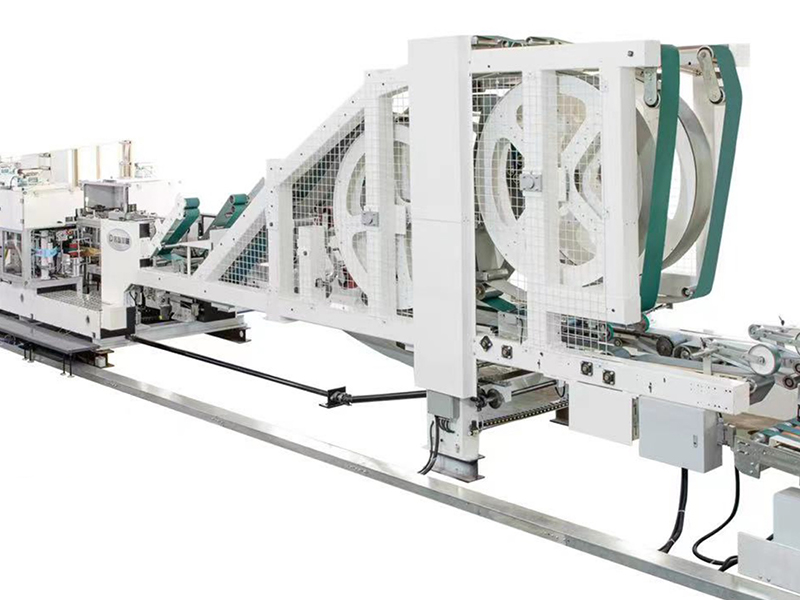

Paper bags have become a sustainable packaging solution in industries worldwide, driving demand for advanced machinery to produce them efficiently. Modern paper bag making machines are engineered to streamline manufacturing processes, ensuring precision, speed, and eco-friendly output. This article explores the technology, operational advantages, and industrial applications of these specialized machines.

Core Components of Paper Bag Making Machines

- Feeding System: Automatically feeds paper rolls into the machine, ensuring consistent material supply.

- Forming Unit: Shapes flat paper into bags using precise folding, creasing, and cutting mechanisms.

- Gluing/Sealing System: Applies adhesives or heat-sealing techniques to secure seams and handles.

- Handle Attachment: Integrates reinforced handles (twisted, flat, or ribbon) for durability.

- Control Panel: A programmable interface for adjusting dimensions, speed, and output parameters.

Operational Advantages

- High-Speed Production: Capable of manufacturing 50–200+ bags per minute, depending on machine specifications.

- Material Versatility: Compatible with kraft paper, recycled paper, and laminated materials.

- Precision Engineering: Ensures uniform bag dimensions and minimal material waste.

- Energy Efficiency: Advanced models reduce power consumption through optimized motor systems.

- Customization: Supports variable sizes, handle types, and printing integrations.

Key Applications

- Retail Packaging: Produces shopping bags with branding capabilities.

- Food Industry: Generates grease-resistant bags for takeout and bakery items.

- E-Commerce: Creates durable mailing bags with reinforced edges.

- Gift Packaging: Enables decorative designs with embossing or foil stamping options.

Selecting the Right Machine

When investing in a paper bag making machine, consider:

- Production Capacity: Match output speed with business demand.

- Material Compatibility: Verify supported paper weights and coatings.

- Automation Level: Choose semi-automatic or fully automated systems based on labor resources.

- Customization Options: Prioritize machines offering flexible design adjustments.

- Compliance: Ensure adherence to safety and environmental standards (e.g., ISO certifications).

Sustainability Impact

These machines support eco-friendly initiatives by enabling the use of biodegradable materials and reducing plastic dependency. Advanced models incorporate waste-reduction technologies, such as scrap recycling systems, to minimize environmental footprint.

Modern paper bag making machines are indispensable for businesses seeking scalable, sustainable packaging solutions. By combining automation, precision, and adaptability, they empower manufacturers to meet diverse market demands while aligning with global environmental goals. Investing in the right equipment ensures long-term competitiveness in the evolving packaging industry.