Advancements in Paper Packaging Machinery: Driving Efficiency and Sustainability in Modern Manufacturing

Release time:2025-05-27 Classification:Knowledge

The global shift toward eco-friendly packaging solutions has positioned paper packaging machinery at the forefront of industrial innovation. As industries prioritize sustainability and operational efficiency, these machines have evolved into sophisticated systems that streamline production while minimizing environmental impact. This article explores the critical role of paper packaging machinery in contemporary manufacturing, highlighting technological advancements, sustainable practices, and their transformative effects on the packaging sector.

The Evolution of Paper Packaging Machinery

Paper packaging machinery has undergone significant transformation over decades, transitioning from manual labor-intensive processes to fully automated, high-speed systems. Modern equipment integrates precision engineering with smart technologies to handle tasks such as folding, sealing, labeling, and quality inspection. Key advancements include servo-driven mechanisms for energy efficiency, programmable logic controllers (PLCs) for adaptive workflows, and vision systems that detect defects in real time. These innovations ensure consistent output while reducing material waste—a critical factor in meeting both economic and environmental goals.

Core Components and Operational Workflows

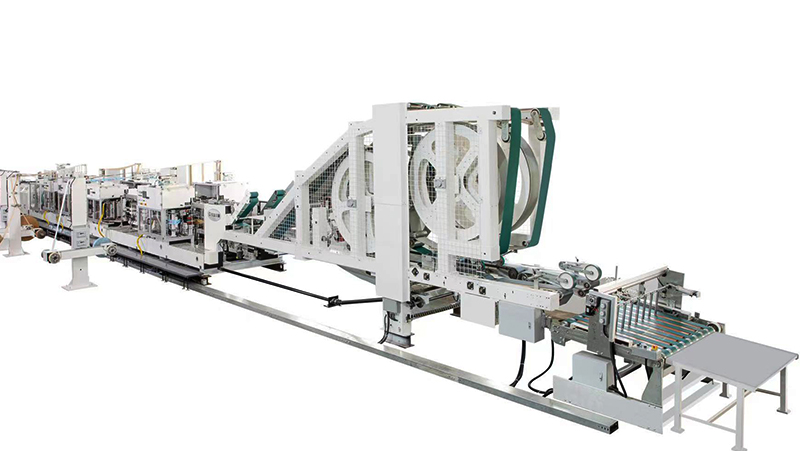

A typical paper packaging line comprises multiple interconnected systems designed for seamless operation:

- Material Feeding and Preparation: Automated unwinders and tension control systems ensure precise alignment of paper rolls, minimizing jams and downtime.

- Forming and Shaping: Die-cutting units and folding modules convert flat paperboard into boxes, trays, or cartons with millimeter-level accuracy.

- Adhesive Application: Eco-friendly glue dispensers apply non-toxic adhesives at controlled volumes, enhancing structural integrity without compromising recyclability.

- Quality Assurance: Integrated sensors and cameras inspect dimensions, print clarity, and seam quality, rejecting substandard units before packaging.

- End-of-Line Handling: Robotic arms stack finished products onto pallets, optimizing logistics readiness.

Such integration not only accelerates production cycles but also supports customization for diverse product shapes and sizes, catering to industries ranging from food and beverage to pharmaceuticals.

Sustainability: A Central Pillar of Design

Environmental responsibility is deeply embedded in modern paper packaging machinery. Manufacturers now prioritize:

- Energy-Efficient Drives: Variable frequency drives (VFDs) reduce power consumption by adjusting motor speeds based on real-time demand.

- Waste Reduction Algorithms: AI-powered systems predict and adjust cutting patterns to maximize material usage, slashing scrap rates by up to 30%.

- Compatibility with Recycled Materials: Advanced feeders and tensioners accommodate recycled paperboard without compromising machine performance.

- Water-Based Inks and Adhesives: Machinery is increasingly designed to work with biodegradable substances, aligning with circular economy principles.

These features enable businesses to meet stringent regulatory standards while appealing to eco-conscious consumers.

Challenges and Maintenance Best Practices

Despite their robustness, paper packaging machines require meticulous upkeep to maintain peak performance. Common challenges include:

- Material Variability: Fluctuations in paper thickness or moisture content can affect forming consistency. Regular calibration of sensors and actuators is essential.

- Adhesive Drying Times: Humidity and temperature controls must be optimized to prevent delays in bonding.

- Wear and Tear: High-speed components like cutting blades and conveyor belts need scheduled lubrication and replacement.

Proactive maintenance strategies—such as predictive analytics via IoT sensors—help preempt failures, extending equipment lifespan and ensuring uninterrupted production.

Future Trends and Industry Outlook

Emerging technologies are set to redefine paper packaging machinery further:

- AI-Driven Optimization: Machine learning algorithms will fine-tune operations in real time, adapting to material changes or order fluctuations.

- Modular Design: Plug-and-play modules will allow factories to reconfigure lines swiftly for new packaging formats, reducing downtime.

- Blockchain Integration: Traceability systems will track raw materials from source to finished product, enhancing supply chain transparency.

As consumer demand for sustainable packaging grows, investments in R&D will focus on enhancing speed, versatility, and eco-performance. Hybrid systems that combine paper with compostable films or coatings are already entering pilot phases, promising new frontiers for the industry.

Paper packaging machinery represents a convergence of engineering excellence and environmental stewardship. By embracing automation, precision, and sustainable design, these systems empower manufacturers to meet the dual challenges of productivity and planetary responsibility. As technology continues to advance, the sector will remain pivotal in shaping a greener, more efficient future for global packaging networks—one box, carton, and tray at a time.