Flexographic Printing Bag Machines: Precision, Efficiency, and Versatility in Modern Packaging

Release time:2025-05-27 Classification:Knowledge

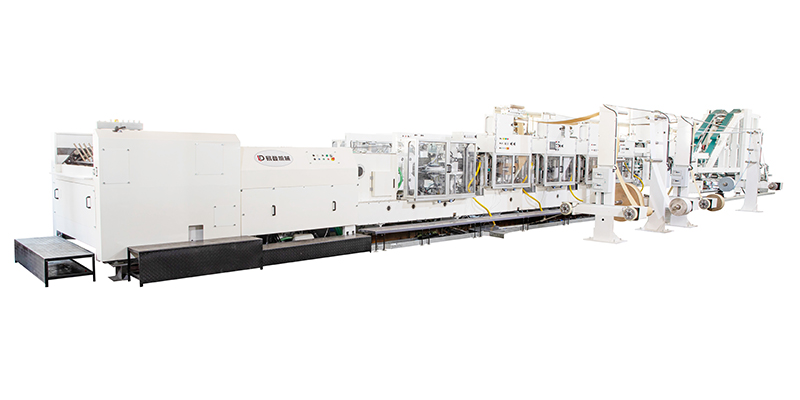

The packaging industry has undergone significant advancements in recent years, with flexographic printing bag machines emerging as a cornerstone technology for producing high-quality, durable, and visually appealing bags. Combining speed, adaptability, and eco-friendly practices, these machines have become indispensable for manufacturers aiming to meet diverse market demands. This article explores the mechanics, advantages, and applications of flexographic printing bag machines, shedding light on why they dominate modern packaging production.

Understanding Flexographic Printing Technology

Flexographic printing, often abbreviated as "flexo," is a rotary printing process that utilizes flexible relief plates to transfer ink onto substrates. When applied to bag manufacturing, flexographic printing bag machines integrate this method with precision cutting, laminating, and sealing systems. The process begins with the creation of custom-designed printing plates, typically made from polymer or photopolymer materials, which are mounted onto cylinders. These plates transfer fast-drying inks—water-based, solvent-based, or UV-curable—onto materials such as polyethylene, polypropylene, or biodegradable films.

The integration of advanced servo-driven systems ensures synchronized operations, enabling high-speed production while maintaining registration accuracy. This technology excels in handling continuous patterns, multicolor designs, and variable data printing, making it ideal for applications ranging from retail packaging to industrial-grade sacks.

Key Components of Flexographic Printing Bag Machines

- Printing Units:

Each machine features multiple printing stations, each dedicated to a specific color or coating. Modern units employ closed-loop color management systems to ensure consistency across batches. Quick-change plate systems minimize downtime during design transitions. - Ink Delivery Systems:

Precision ink pumps and anilox rollers regulate ink flow, delivering optimal coverage without oversaturation. Eco-friendly ink formulations reduce VOC emissions, aligning with sustainability goals. - Substrate Handling Mechanisms:

Tension control systems maintain uniform material feed, preventing wrinkles or misalignment. Some machines support multilayer laminates for barrier properties (e.g., moisture resistance). - Die-Cutting and Sealing Modules:

Rotary dies cut bags into predefined shapes, while heat-sealing jaws create airtight closures. Laser-guided sensors ensure precise cuts and seals, even at speeds exceeding 500 meters per minute. - Automated Quality Control:

Vision inspection systems detect defects like misprints or incomplete seals, triggering real-time adjustments or rejections.

Advantages Over Alternative Technologies

Flexographic printing bag machines outperform competing methods such as gravure or offset printing in several ways:

- Speed: Capable of producing thousands of bags per hour, flexo machines maximize throughput for large orders.

- Material Flexibility: They accommodate diverse substrates, including thin films, woven fabrics, and recyclable materials.

- Cost-Effectiveness: Lower plate costs and reduced waste make flexo printing economical for short-to-medium runs.

- Sustainability: Water-based inks and energy-efficient dryers minimize environmental impact.

Applications Across Industries

The versatility of flexographic printing bag machines makes them suitable for:

- Food Packaging: Printed stand-up pouches, resealable bags, and breathable films for fresh produce.

- Pharmaceuticals: Child-resistant pouches with tamper-evident seals and high-resolution branding.

- Agriculture: UV-resistant fertilizer sacks and seed bags with weatherproof coatings.

- Retail & E-commerce: Custom-printed reusable shopping bags and mailer envelopes.

Trends Shaping the Future

As industries prioritize sustainability and customization, flexographic printing bag machines are evolving to address these needs:

- Digital Hybrid Systems: Combining flexo with digital printing for variable data (e.g., QR codes, batch numbers).

- Biodegradable Inks and Substrates: Innovations in compostable materials reduce landfill waste.

- IoT Integration: Predictive maintenance and remote monitoring enhance operational efficiency.

Flexographic printing bag machines represent the pinnacle of packaging innovation, blending speed, precision, and environmental responsibility. Their ability to adapt to shifting market trends—whether through advanced automation or sustainable practices—ensures their continued relevance in a competitive global landscape. For manufacturers seeking to elevate their packaging capabilities, investing in flexographic technology is not just a choice but a strategic imperative.

By mastering the balance between quality and efficiency, these machines empower businesses to deliver products that captivate consumers while adhering to rigorous industrial and ecological standards. As technology progresses, flexographic printing will undoubtedly remain at the forefront of the packaging revolution.