Small Paper Bag Making Machine: Comprehensive Guide to Features, Benefits, and Applications

Release time:2025-05-06 Classification:Knowledge

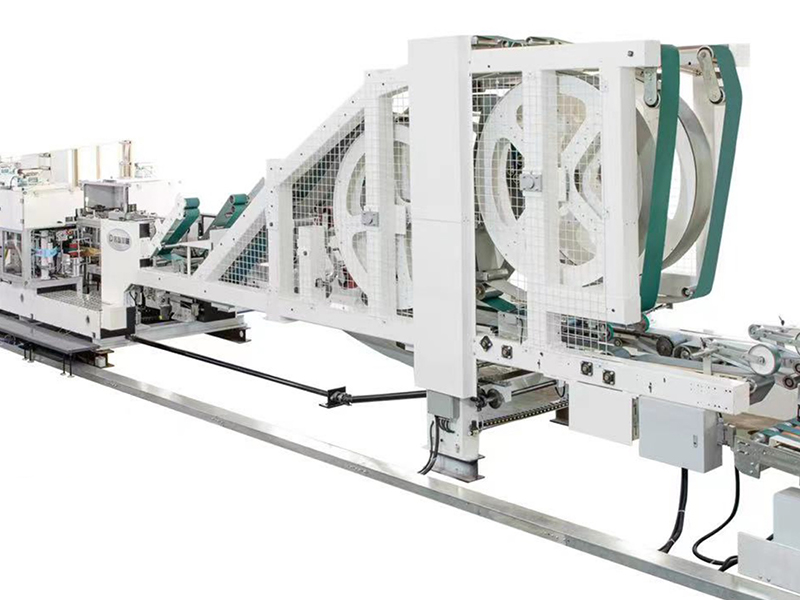

A small paper bag making machine is a specialized piece of equipment designed to automate the production of eco-friendly, customizable paper bags. Ideal for businesses seeking sustainable packaging solutions, these machines cater to small- and medium-scale operations by combining efficiency with versatility. This guide explores the technical aspects, advantages, and practical uses of small paper bag making machines, providing insights for businesses aiming to enhance their packaging workflows.

How a Small Paper Bag Making Machine Works

These machines streamline the bag production process through a series of automated steps:

- Material Feeding: Rolls of kraft paper or recycled paper are loaded into the machine.

- Printing (Optional): Some models include integrated printing units for branding or design applications.

- Cutting and Folding: Precision blades cut the paper to size, followed by automated folding to form the bag’s structure.

- Gluing and Sealing: Food-grade adhesives secure the seams and base, ensuring durability.

- Output: Finished bags are stacked for packaging or direct use.

Key Benefits of Small Paper Bag Making Machines

- Cost Efficiency: Reduces labor costs and material waste through automation.

- Eco-Friendly: Supports sustainable packaging by using recyclable or biodegradable materials.

- Customization: Enables adjustable sizes, handles (twisted or flat), and optional printing.

- Compact Design: Occupies minimal space, ideal for workshops or small facilities.

- High Output: Capable of producing hundreds of bags per hour, depending on the model.

Applications Across Industries

Small paper bag making machines serve diverse sectors:

- Retail Stores: Create branded shopping bags for boutiques or supermarkets.

- Food Industry: Produce grease-resistant bags for bakeries, cafes, or takeout services.

- Gift Packaging: Craft decorative bags for events, weddings, or specialty stores.

- Sustainability Initiatives: Align with zero-waste goals by replacing plastic packaging.

Choosing the Right Machine

When selecting a small paper bag making machine, consider:

- Production Capacity: Match output speed (bags/hour) to your business needs.

- Customization Options: Prioritize machines with adjustable dimensions and handle types.

- Material Compatibility: Ensure compatibility with varying paper weights and recycled materials.

- Energy Consumption: Opt for energy-efficient models to reduce operational costs.

- After-Sales Support: Verify availability of technical assistance and spare parts.

A small paper bag making machine is a strategic investment for businesses prioritizing sustainability and operational efficiency. By automating production, these machines empower brands to meet growing demand for eco-conscious packaging while maintaining flexibility in design and scalability. Whether for retail, food services, or custom packaging, integrating this technology enhances both productivity and environmental responsibility