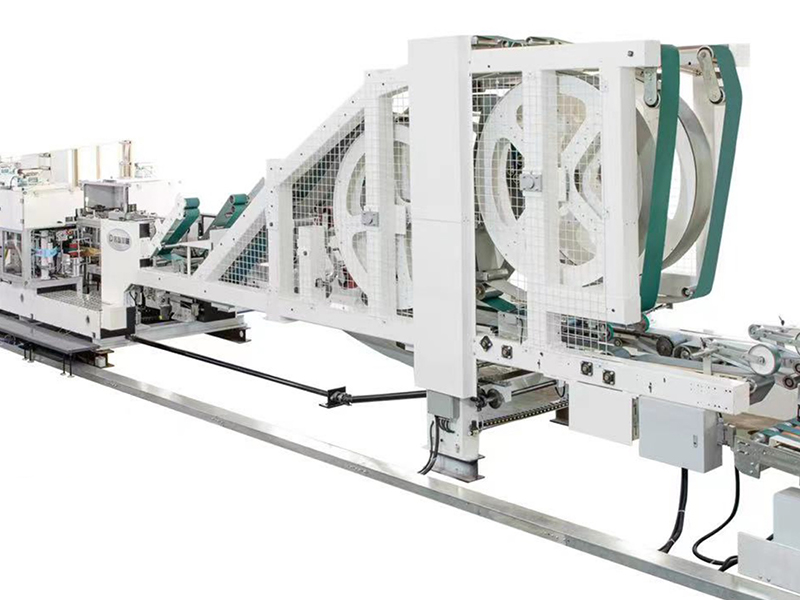

The YD-5875 Tuber Machine is a state-of-the-art industrial solution designed for high-efficiency production of paper bag tubes. Engineered to deliver precision, speed, and versatility, this machine supports a wide range of bag dimensions and integrates seamlessly with multi-color printing systems, making it ideal for modern packaging manufacturing.

Key Features & Capabilities

- Production Range

- Bag Width: 300–750 mm

- Bag Length: 410–1650 mm

- Adaptable to diverse packaging requirements for industries such as food, retail, and logistics.

- High-Speed Operation

- Maximum output of 450 pieces per minute, ensuring rapid production cycles.

- Compatible with 4-color or 6-color printers for vibrant, multi-color designs.

- Modular Design & Workflow

The machine’s 11 integrated stations ensure streamlined operations:- Paper Roll Unwinding Station: Ensures continuous material feeding.

- PP/PE Film Feeding Station: Supports laminated or coated bag production.

- Edge Correction & Positioning: Maintains alignment accuracy (±1 mm).

- Perforation & Punching Unit: Customizable hole patterns for handles or vents.

- Tension Control System: Prevents material slippage or wrinkling.

- Stepped Cutting Mechanism: Enables variable-length tube sections.

- Cross & Longitudinal Adhesive Application: Precision glue placement for secure seams.

- Tube Forming Section: Converts flat sheets into cylindrical tubes.

- Flush Cutting & Traction Unit: Delivers clean, uniform cuts.

- Automated Stacking & Packaging: Includes counting and conveyor systems for end-of-line efficiency.

- Robust Construction

- Dimensions: 36 m (L) × 3.5 m (W) × 3.1 m (H)

- Weight: 45 tons

- Power Consumption: 50 kW

Built for durability and minimal downtime, the machine’s heavy-duty frame ensures stability during high-speed runs.

Technical Advantages

- Precision Engineering: Advanced servo motors and PLC controls guarantee consistent quality.

- Flexible Configuration: Easily adjustable settings for rapid product changeovers.

- Energy Efficiency: Optimized power usage reduces operational costs.

Applications

Ideal for producing shopping bags, gift bags, and industrial packaging tubes with printed designs. Its compatibility with PP/PE films also allows for waterproof or reinforced bag manufacturing.

The YD-5875 Tuber Machine sets a benchmark in paper bag production technology, combining speed, precision, and scalability. Its modular design and automation features make it a cost-effective investment for businesses aiming to enhance productivity and meet evolving market demands.