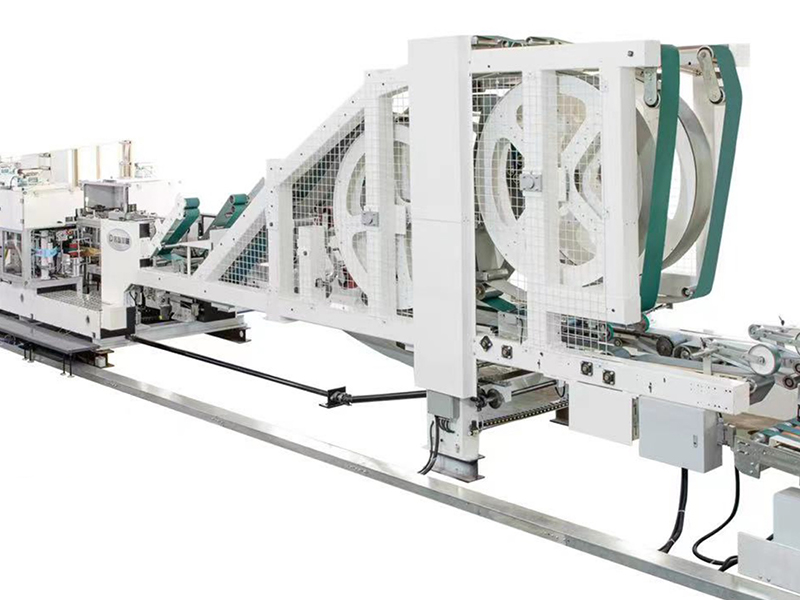

The Bottomer Machine YD-2825 is a precision-engineered system designed for the efficient production of paper bag valve ports and bottoms. Capable of handling bag widths from 300mm to 750mm and bottom widths from 90mm to 250mm, this machine delivers exceptional versatility for industrial-scale paper bag manufacturing. With a maximum output of 300 pieces per minute, it optimizes productivity while maintaining consistent quality across diverse bag specifications.

Key Components and Functional Modules

The YD-2825 comprises 14 modular units, enabling customization based on production requirements:

- Rotary Feeder Unit

Ensures seamless paper tube feeding and alignment. - Tube Aligner

Automatically ejects misaligned tubes to prevent production errors. - Diagonal Creasing & Bottom Formation

Performs center creasing, bottom opening, and precision diagonal folding. - Primary Valve Port Positioning

Integrates thumb-cutting and material dislocation functions for valve ports (90–270mm). - Secondary Valve Port Position (Optional)

Adds flexibility for dual-valve configurations. - Internal Valve Reinforcement (Optional)

Applies 200–450mm reinforcement patches for enhanced durability. - Bottom Pasting & Capping

Combines adhesive application with intermediate pressing for secure bonding. - Bottom Closing/Forming

Ensures precise fold alignment and structural integrity. - External Bottom Reinforcement (Optional)

Applies 200–500mm reinforcement strips for heavy-duty applications. - Bottom Turning Mechanism

Orients bags for downstream processes. - Large S-Bag Pressing System

Flattens bags and ensures even glue distribution. - Counting & Stacking Unit

Automates output organization for streamlined packaging. - Bottom Printing Paper Roller Stand

Supports inline branding or labeling. - Centralized Electrical Cabinet

Houses advanced control systems for operational safety and efficiency.

Technical Specifications

- Production Speed: 250–300 pcs/min

- Bag Dimensions:

- Width: 300–720mm

- Length: 410–1450mm

- Center Distance: 200–1350mm

- Bottom Width Range: 90–250mm

- Machine Dimensions (L×W×H): 36m × 5m × 3.1m

- Power Consumption: 50KW

- Weight: 60 metric tons

Operational Advantages

- Adaptive Design: Modular architecture allows customization for valve types, reinforcements, and printing needs.

- Precision Engineering: Advanced creasing and alignment systems minimize material waste.

- Scalable Output: High-speed operation meets large-volume production demands without compromising accuracy.

- Durability: Robust construction ensures long-term reliability in continuous industrial environments.

The Bottomer Machine YD-2825 represents a state-of-the-art solution for manufacturers seeking to optimize paper bag production efficiency. Its combination of modular flexibility, high-speed performance, and precision control makes it an essential asset for operations targeting diverse market requirements—from standard retail packaging to specialized industrial applications. By integrating optional reinforcements and automation features, this machine ensures consistent output quality while reducing manual intervention and operational costs.