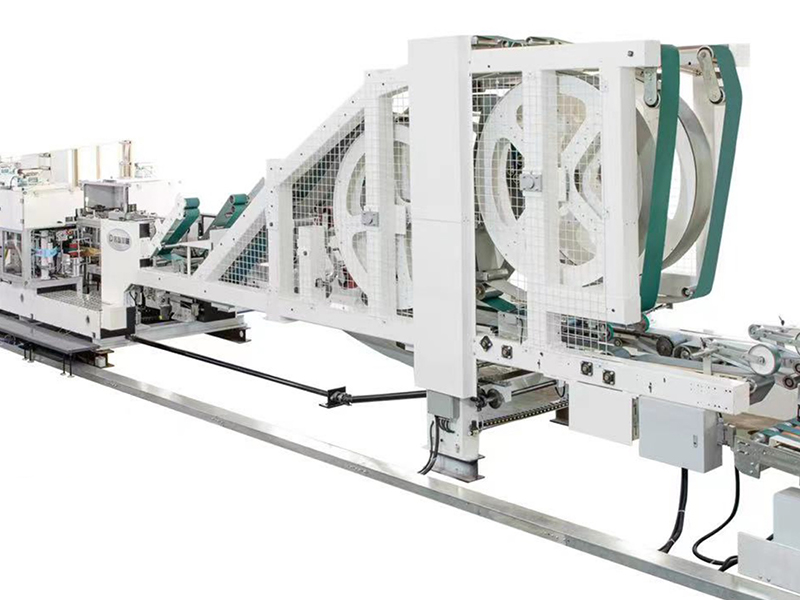

Introducing the YD-5860 Tuber Machine: Advanced Automation for Precision Paper Bag Tube Manufacturing

The YD-5860 tuber machine is a state-of-the-art industrial solution designed for high-efficiency production of paper bag tubes. Engineered to meet diverse manufacturing demands, this machine delivers exceptional performance, precision, and adaptability for producing paper bags with widths ranging from 300mm to 600mm and lengths from 410mm to 1250mm. With a production speed of up to 450 pieces per minute, the YD-5860 ensures rapid output while maintaining consistent quality, making it ideal for large-scale industrial applications.

Key Features and Technical Specifications

- Compatibility: Seamlessly integrates with 4-color or 6-color printers, enabling vibrant, multi-color printing on paper tubes.

- Modular Design: The machine is systematically divided into 11 functional stations for streamlined operations:

- Paper Roll Feeding Station: Ensures continuous material supply.

- PP/PE Film Feeding Station: Supports laminated or coated tube production.

- Edge Correction & Positioning: Maintains precise alignment for uniform output.

- Perforation & Punching Unit: Adds functional or decorative elements.

- Tension Control System: Guarantees stable material handling.

- Stepped Cutting Mechanism: Enables customizable bag designs.

- Cross Adhesive Application: Secures transverse bonding.

- Longitudinal Adhesive System: Ensures seamless tube formation.

- Tube Forming Section: Shapes paper into durable tubes.

- Cutting, Traction & Separation: Delivers clean, flush cuts for finished bags.

- Stacking, Counting & Packaging: Automates post-production workflows.

- High-Speed Performance: Operates at 450pcs/min, maximizing productivity without compromising accuracy.

- Robust Construction: Built with durable components, the machine measures 36m (L) × 3.5m (W) × 3.1m (H) and weighs 4 tons, ensuring long-term reliability.

- Energy Efficiency: Total power consumption of 50KW balances performance with operational cost-effectiveness.

Applications & Advantages

The YD-5860 tuber machine is engineered for versatility, catering to industries requiring custom-sized paper bags, such as packaging, food, retail, and logistics. Its ability to handle varying bag dimensions (width: 300–600mm, length: 410–1250mm) makes it suitable for producing grocery bags, gift bags, and industrial-grade packaging solutions. Advanced features like tension control and edge correction ensure minimal material waste, while the automated stacking system reduces labor dependency.

Why Choose the YD-5860?

- Precision Engineering: Guarantees consistent tube formation and adhesive application.

- Scalable Production: Adapts to high-volume demands with minimal downtime.

- User-Friendly Operation: Simplified controls and modular design ease maintenance.

For manufacturers seeking a reliable, high-speed solution for paper bag tube production, the YD-5860 tuber machine sets a new benchmark in efficiency, flexibility, and quality. Its integration-ready design and advanced automation capabilities make it a cornerstone of modern packaging production lines.