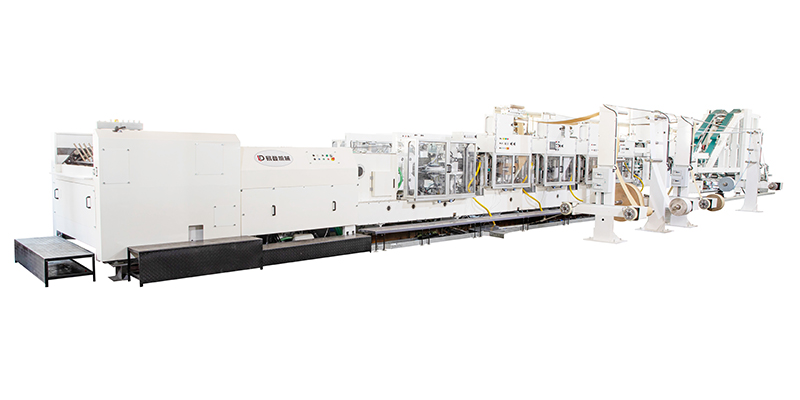

Valve Paper Bag Machines-Factory-Direct Supplier of High-Efficiency Valve Bag Production Equipment

Release time:2025-04-26 Classification:Company News

Valve bags are widely used in industries such as chemical, building materials, and food for packaging powdered or granular materials due to their excellent sealing performance, high loading efficiency, and ease of transportation. With increasingly stringent environmental policies and growing demand for packaging automation, high-efficiency and stable valve paper bag machines have become critical equipment for enterprises to enhance competitiveness. As a professional manufacturer of valve paper bag machines, Yideng Machinery empowers clients to achieve intelligent and large-scale production through self-developed technologies, a factory-direct supply model, and cost-effective solutions.

Core Applications of Valve Paper Bag Machines

Valve bags feature a unique "valve" design that enables self-sealing after filling, preventing material leakage. They are particularly suitable for packaging products like cement, gypsum powder, and animal feed. Traditional manual bag-making processes suffer from low efficiency, high costs, and difficulty meeting precision requirements for mass production. Fully automatic valve paper bag machines achieve high-speed production of hundreds of bags per minute through precise processes such as paper feeding, edge folding, bottom pasting, and valve forming. These machines ensure bag strength and sealing performance, significantly improving packaging efficiency and product qualification rates.

Yideng Machinery’s valve paper bag machines are designed to meet diverse industry needs, supporting flexible adjustments to paper weights, bag sizes, and specialized processes such as square-bottom valves and M-fold edges, catering to varied production scenarios.

Core Advantages of Yideng Machinery’s Valve Paper Bag Machines

- Advanced Technology, Superior Stability

Equipped with high-precision servo control systems and modular structural design, the machines ensure synchronized operations in paper feeding, forming, and pasting, minimizing downtime. An intelligent temperature-controlled pasting system supports eco-friendly water-based adhesives, delivering strong bonding without volatile emissions, fully complying with green production standards. - Factory-Direct Supply, Cost Efficiency

As an original equipment manufacturer (OEM), Yideng Machinery eliminates middleman markups, offering prices 15%-25% lower than comparable market products. Customization options range from single machines to complete production lines, enabling SMEs to upgrade capacity with minimal investment. - Energy Efficiency, Long-Term Savings

High-efficiency energy-saving motors and intelligent power adjustment systems reduce energy consumption by 20% compared to traditional models, significantly cutting long-term operational costs. Automated production reduces reliance on manual labor, requiring only 1-2 operators per shift to lower overall production expenses.

Key Considerations for Choosing a Valve Paper Bag Machine

- Production Capacity Matching: Select models based on daily output requirements (e.g., 50,000-200,000 bags/day) to avoid underutilization or overloading.

- Material Compatibility: Ensure compatibility with kraft paper, laminated paper, and specialized treatments like moisture-proof and tear-resistant coatings.

- After-Sales Support: Prioritize suppliers offering on-site installation, operator training, and technical support to ensure seamless operations.

Yideng Machinery provides end-to-end services, from equipment selection and factory layout planning to production training. With a 12-hour response time and 48-hour solution guarantee, we ensure uninterrupted production for clients.

Conclusion

Amid the intelligent and eco-friendly transformation of the packaging industry, Yideng Machinery’s valve paper bag machines stand out for their precision, cost-effectiveness, and reliable service, making them the preferred choice for businesses. Whether you are a startup or a large-scale enterprise, we offer tailor-made production solutions. Contact us today for a free trial and customized quotation to unlock a new era of efficient valve bag production!

This translation maintains the technical accuracy and promotional tone of the original text while adapting terminology and structure for clarity in English. Key terms like "valve bag," "servo control systems," and "eco-friendly water-based adhesives" are carefully localized to resonate with industry standards.