Cement Bag Production Line Manufacturer Recommendation | High-Stability Cement Packaging Equipment Brand

Release time:2025-04-26 Classification:Company News

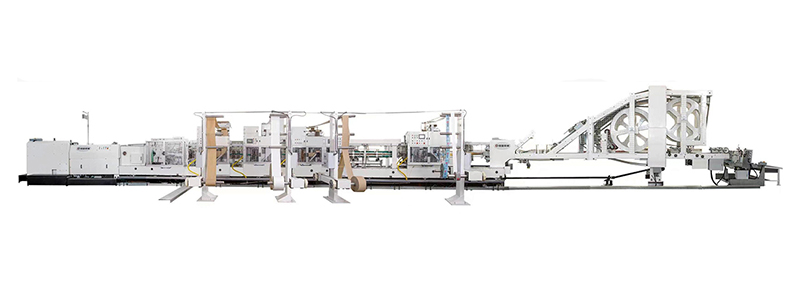

With the rapid development of the construction and building materials industries, cement bags—as critical packaging carriers—directly impact enterprise productivity and cost control through their production efficiency and equipment reliability. Yideng Machinery, a professional manufacturer of cement bag production lines, delivers high-stability, durable, and integrated cement packaging equipment solutions to global clients through its technical R&D capabilities and factory-direct supply model.

Core Requirements & Industry Pain Points in Cement Bag Production Lines

Cement bags demand high tensile strength, moisture resistance, and wear resistance, requiring production equipment to meet the following criteria:

- High-strength material processing capabilities: Precise cutting and stitching for multi-layer kraft paper, laminated woven bags, and other thick materials.

- Continuous high-efficiency production: Stable 24/7 operation with low failure rates to meet bulk order demands in the cement industry.

- Automation upgrades: Reduced manual intervention via intelligent error correction, automatic counting, and quality control to enhance packaging yield.

Traditional equipment often suffers from thread breakage, material jams, and insufficient precision, leading to frequent downtime. Yideng Machinery’s purpose-developed cement bag production line adopts modular design to optimize core processes like material feeding, forming, and bottom stitching, achieving high daily output and helping enterprises overcome capacity bottlenecks.

Four Core Advantages of Yideng Machinery’s Cement Bag Production Lines

- Factory-Direct Supply, Cost Efficiency

As an OEM, Yideng Machinery eliminates intermediaries, offering prices 15%-25% below market average while supporting customized configurations. - Technical Excellence, Superior Performance

- High-rigidity frame structures and imported servo drive systems ensure long-term heavy-duty operation.

- Intelligent temperature and pressure control adapt to varying material weights, minimizing waste.

- One-click switching between bag specifications (e.g., 50kg, 25kg standard or custom sizes) enhances line flexibility.

- Energy Savings & Long-Term Durability

High-efficiency energy-saving motors and low-friction transmission components reduce energy consumption by 20%, while wear-resistant alloy steel critical parts extend service life by 30%+. - Global Service Network, Hassle-Free Support

Free installation, training, and technical support, backed by a global service network for rapid response, ensuring uninterrupted production.

How to Choose a Cost-Effective Cement Bag Production Line?

- Define capacity needs: Select models based on daily production volume and bag type complexity.

- Prioritize stability: Evaluate real-world case studies to verify continuous uptime and failure rates.

- Assess manufacturer credentials: Opt for brands with proprietary technologies, large-scale production facilities, and robust after-sales systems.

Yideng Machinery supports on-site factory inspections and sample machine trials, allowing clients to validate performance with real production data. We also provide full lifecycle management services, covering everything from procurement to maintenance upgrades.

Conclusion

Amid intensifying competition in the cement packaging industry, selecting a reliable production line is key to profitability. Yideng Machinery, with its high-stability equipment, factory-direct pricing, and global service capabilities, has become a trusted long-term partner for enterprises worldwide. Contact us now for a tailored solution and unlock a new era of efficient, low-cost cement bag manufacturing!

This translation emphasizes technical precision, cost-efficiency, and reliability, aligning with the original text’s focus on industrial demands and competitive advantages. Key terms like "servo drive systems," "modular design," and "wear-resistant alloy steel" are carefully localized to resonate with global cement industry standards.