Innovations in Industrial Paper Sack Making Machinery: Efficiency and Sustainability in Modern Packaging

Release time:2025-05-26 Classification:Knowledge

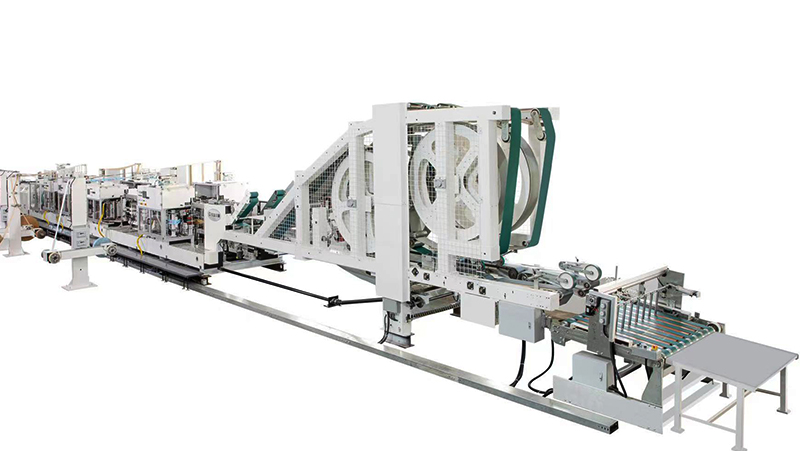

The production of industrial paper sacks has evolved significantly over the decades, driven by advancements in machinery designed to meet the demands of durability, speed, and environmental responsibility. Industrial paper sack making machines are at the core of this transformation, enabling manufacturers to produce high-quality packaging solutions for industries such as agriculture, construction, chemicals, and food. This article explores the technical features, operational benefits, and sustainability advantages of modern industrial paper sack manufacturing equipment.

Key Components and Workflow of Paper Sack Making Machines

A state-of-the-art industrial paper sack making machine integrates multiple subsystems to automate the entire production process. The primary stages include:

- Unwinding and Material Handling: High-precision rollers feed kraft paper or multi-layer laminated materials into the system, ensuring consistent tension control to avoid wrinkles or tears.

- Tube Forming and Gluing: The machine forms paper into a tubular structure using heated mandrels or forming shoulders, with adhesive applied seamlessly to create strong longitudinal seams.

- Bottom Folding and Sealing: Rotary mechanisms fold and secure the sack bottoms, employing advanced sealing techniques such as hot melt adhesives or stitching for leak-proof performance.

- Printing and Embossing: Integrated flexographic or digital printing units apply logos, safety warnings, or product information, while embossing units enhance grip and branding.

- Cutting and Stacking: Servo-driven blades cut sacks to precise lengths, after which automated stacking systems organize finished products for palletizing.

Technological Advancements Driving Efficiency

Modern industrial paper sack machines leverage cutting-edge technologies to optimize productivity:

- Servo Motor Systems: Replace traditional mechanical drives, enabling programmable speed adjustments, reduced energy consumption, and smoother motion control.

- IoT-Enabled Monitoring: Real-time sensors track parameters like temperature, glue viscosity, and motor torque, allowing predictive maintenance and minimizing downtime.

- Modular Design: Configurable modules allow manufacturers to switch between sack types (e.g., valve sacks, open-mouth sacks) without lengthy reconfiguration.

- High-Speed Production: Advanced models achieve outputs exceeding 120 sacks per minute while maintaining micron-level precision in seam alignment.

Sustainability Features

As global industries prioritize eco-friendly packaging, paper sack machinery has adapted to support circular economy goals:

- Material Optimization: AI-driven algorithms calculate minimal paper usage per sack without compromising strength, reducing raw material waste by up to 15%.

- Energy Recovery Systems: Heat generated during drying stages is recycled to preheat incoming materials, cutting overall energy demands.

- Water-Based Adhesives: Replace solvent-based alternatives, lowering VOC emissions and ensuring compliance with food-grade safety standards.

- Recyclability Compliance: Machines are engineered to produce sacks free from mixed materials, facilitating end-of-life recycling.

Quality Control and Precision

Consistency is critical in industrial packaging. Modern machines incorporate:

- Laser-Guided Inspection: Cameras and laser scanners detect defects like uneven glue application or misaligned prints, triggering automatic reject systems.

- Tensile Strength Testing: In-line sensors validate seam integrity by simulating real-world load conditions.

- Humidity Control: Climate-controlled zones maintain paper moisture levels, preventing dimensional instability during storage.

Adaptability to Market Trends

The flexibility of contemporary paper sack machines addresses emerging industry needs:

- Multi-Ply Construction: Capable of bonding 2–6 layers of paper or barrier films for heavy-duty applications (e.g., cement, fertilizers).

- Hybrid Material Compatibility: Process recycled paper blends or biodegradable coatings without operational interruptions.

- Customization at Scale: Quick-change tooling supports small-batch production runs for niche markets.

Maintenance and Operational Safety

Robust safety protocols and user-friendly interfaces define newer generations of equipment:

- Self-Lubricating Components: Reduce manual intervention and extend machinery lifespan.

- Ergonomic Access Points: Facilitate easy cleaning and part replacement during scheduled maintenance.

- Emergency Stop Systems: Redundant sensors halt operations instantly if anomalies are detected.

Future Outlook

The industrial paper sack machinery sector continues to innovate, with R&D focusing on:

- AI-Powered Predictive Analytics: Anticipate wear-and-tear patterns to optimize maintenance schedules.

- Carbon-Neutral Operations: Integration of solar-powered drives and bio-based hydraulic fluids.

- Smart Packaging Integration: Embedding RFID tags or QR codes during production for supply chain traceability.

In conclusion, industrial paper sack making machines represent a synergy of engineering precision and environmental stewardship. By combining high-speed automation with sustainable practices, these systems empower manufacturers to meet the dynamic needs of global markets while adhering to stringent ecological standards. As technology progresses, the role of advanced machinery in shaping the future of paper-based packaging will only grow more pivotal.