Paper Bag Converting Machines: Essential Technology for Modern Packaging Solutions

Release time:2025-05-22 Classification:Knowledge

In today's environmentally conscious market, paper bags have emerged as a sustainable alternative to single-use plastics, driving demand for efficient and precise manufacturing equipment. At the heart of this production process lies the paper bag converting machine—a sophisticated system that transforms raw materials into high-quality, customizable packaging. As a leader in industrial machinery innovation, Yideng Machinery specializes in delivering cutting-edge converting solutions tailored to meet the evolving needs of the packaging industry.

Understanding Paper Bag Converting Machines

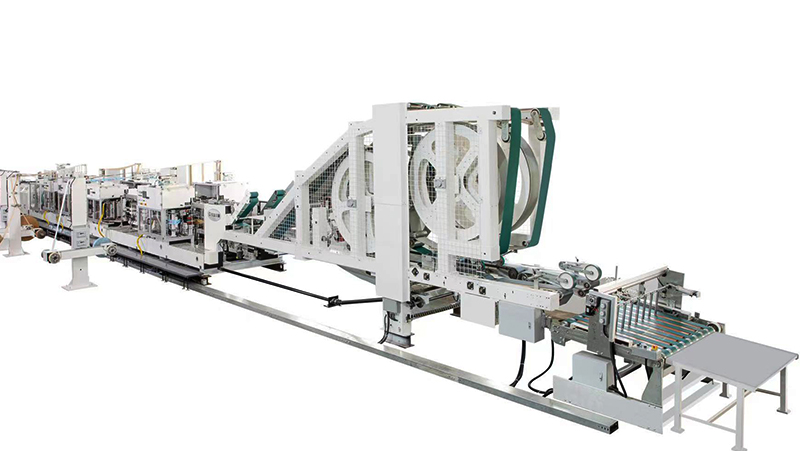

A paper bag converting machine is an integrated production line designed to automate the creation of paper bags from flat rolls of kraft paper or other eco-friendly materials. The process typically involves multiple stages, including unwinding, printing (if required), gluing, folding, bottom sealing, handle attachment, and stacking. These machines are engineered to handle diverse bag styles—such as flat handle bags, twisted handle bags, or satchel bags—with precision and speed.

Advanced models incorporate servo-driven mechanisms and programmable logic controllers (PLCs) to ensure consistent output while minimizing material waste. Modern systems also feature user-friendly interfaces, enabling operators to adjust parameters like bag dimensions, handle positions, and production speed effortlessly. For businesses aiming to scale their operations, these machines offer a critical balance between versatility, productivity, and cost-effectiveness.

Key Applications and Market Demand

The versatility of paper bag converting machines makes them indispensable across industries. Retail brands rely on custom-printed paper bags for branding, while grocery chains prioritize durable designs for heavy loads. Food service providers demand grease-resistant options, and luxury goods manufacturers seek premium finishes. Additionally, the global shift toward biodegradable packaging has expanded applications in e-commerce, pharmaceuticals, and hospitality.

Yideng Machinery's solutions address these varied requirements by supporting a wide range of paper grades, from standard kraft to recycled or laminated materials. Our machines can produce bags with reinforced handles, gusseted sides, or specialized coatings—all while maintaining compliance with international quality and safety standards.

Technological Advancements in Converting Equipment

Innovation remains central to optimizing paper bag production. Yideng Machinery’s R&D team focuses on three core areas:

- Energy Efficiency: Incorporating regenerative drives and low-power components to reduce operational costs.

- Smart Automation: Implementing IoT-enabled sensors for real-time monitoring of machine performance and predictive maintenance.

- Flexibility: Modular designs that allow quick reconfiguration for different bag styles or materials, minimizing downtime during product changeovers.

For instance, our flagship model features laser-guided alignment systems to ensure perfect handle placement and an ultrasonic sealing technology that eliminates the need for adhesives in certain applications. Such advancements not only enhance product consistency but also align with sustainability goals by reducing glue consumption.

Why Choose Yideng Machinery?

With over two decades of expertise in packaging machinery, Yideng Machinery stands at the forefront of paper bag converting technology. Our commitment to excellence is reflected in:

- Precision Engineering: Every component undergoes rigorous testing to guarantee durability and performance under high-volume production.

- Customization Capabilities: Tailored solutions for businesses of all sizes, from startups to multinational corporations.

- Comprehensive Support: End-to-end services including installation, operator training, and 24/7 technical assistance.

Moreover, we prioritize eco-friendly designs, ensuring our machines minimize scrap generation and support the use of recyclable materials. By partnering with Yideng Machinery, clients gain access to future-proof technology that adapts to market trends while maintaining operational efficiency.

The Future of Paper Bag Manufacturing

As regulations on plastic packaging tighten globally, investments in paper-based solutions will continue to rise. Modern converting machines must not only keep pace with demand but also address challenges like rising raw material costs and labor shortages. Yideng Machinery’s automated systems provide a strategic advantage by streamlining workflows, reducing human error, and maximizing output.

Looking ahead, we are exploring AI-driven quality control systems and hybrid energy solutions to further revolutionize the industry. Our goal is to empower manufacturers to produce sustainable, high-value packaging without compromising profitability.

Paper bag converting machines represent a vital link in the sustainable packaging supply chain, combining engineering ingenuity with environmental responsibility. For businesses seeking reliable, scalable, and innovative equipment, Yideng Machinery offers unparalleled expertise and state-of-the-art solutions. Whether you’re launching a new product line or upgrading existing infrastructure, our team is dedicated to helping you achieve operational excellence in an increasingly competitive market.

Explore Yideng Machinery’s range of paper bag converting systems today, and discover how our technology can elevate your packaging capabilities while contributing to a greener planet.