Advanced Cement Bag Making Machine: Enhancing Efficiency in Modern Packaging Solutions

Release time:2025-05-21 Classification:Knowledge

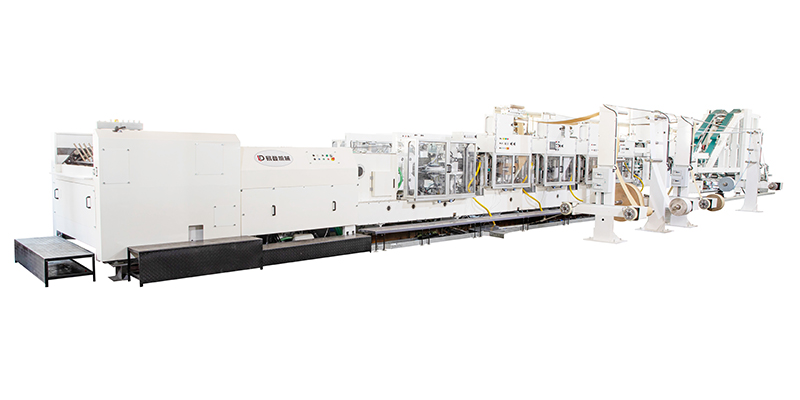

In the dynamic world of industrial packaging, the demand for durable, cost-effective, and sustainable solutions continues to grow. Among the critical innovations driving this sector forward is the cement bag making machine—a cornerstone of modern manufacturing processes. As a leader in engineering robust packaging equipment, Yideng Machinery has pioneered cutting-edge technologies to meet the evolving needs of industries worldwide. This article explores the functionality, benefits, and technological advancements of cement bag making machines, underscoring their role in optimizing production efficiency.

Understanding Cement Bag Making Machines

A cement bag making machine is a specialized piece of equipment designed to automate the production of high-quality cement bags. These machines transform raw materials such as woven polypropylene (PP) or paper into finished bags capable of withstanding heavy loads, environmental stress, and rigorous handling. The process typically involves multiple stages, including material feeding, printing, cutting, folding, and stitching, all streamlined into a seamless workflow.

Key Components and Workflow

- Material Unwinding System: Rolls of base material (e.g., PP fabric) are fed into the machine, ensuring consistent tension and alignment.

- Printing Unit: High-precision printers apply brand logos, product information, or safety warnings onto the fabric.

- Loop Handling Mechanism: Creates the reinforced top loops critical for easy handling and stacking.

- Bottom Folding and Stitching: Automated folders and stitchers secure the bag's base, ensuring structural integrity.

- Cutting and Discharge: Finished bags are cut to size and ejected for packaging or further processing.

Technological Advancements in Cement Bag Production

Modern cement bag making machines integrate state-of-the-art technologies to maximize output while minimizing waste. Yideng Machinery’s innovations include:

- PLC Control Systems: Programmable logic controllers enable precise adjustments to bag dimensions, print patterns, and production speed, ensuring uniformity across batches.

- Energy-Efficient Drives: Servo motors reduce power consumption by up to 30%, aligning with global sustainability goals.

- Fault Detection Sensors: Real-time monitoring systems identify and resolve issues like material misalignment or stitching errors, minimizing downtime.

- Modular Design: Customizable configurations allow manufacturers to adapt the machine for different bag sizes, materials, or printing requirements.

Benefits of Partnering with Yideng Machinery

For over two decades, Yideng Machinery has been at the forefront of designing and manufacturing cement bag making machines tailored to diverse industrial needs. Our commitment to excellence is reflected in several core advantages:

- Unmatched Durability: Machines are built with high-grade components to withstand 24/7 operation in demanding environments.

- Scalable Solutions: From semi-automatic models for small-scale producers to fully automated lines for large factories, we offer equipment that grows with your business.

- Reduced Operational Costs: Advanced automation lowers labor expenses, while precision engineering reduces material waste by up to 15%.

- Global Compliance: Our machines adhere to international safety and quality standards, including ISO certifications, ensuring seamless integration into global supply chains.

Applications Beyond Cement Packaging

While cement bag production remains a primary application, Yideng Machinery’s equipment is versatile enough to handle other materials such as:

- Agricultural products (e.g., fertilizer, animal feed)

- Chemicals and minerals

- Food-grade packaging (with optional food-safe material compatibility)

Maintenance and Longevity

To ensure peak performance, regular maintenance is essential. Yideng Machinery provides comprehensive support, including:

- Predictive Maintenance Software: Analyzes machine data to schedule timely servicing.

- On-Demand Technical Support: A global network of engineers offers rapid troubleshooting and spare parts delivery.

- Operator Training Programs: Hands-on workshops to maximize equipment utilization and safety.

The Future of Cement Bag Manufacturing

As industries prioritize sustainability, Yideng Machinery continues to innovate. Emerging trends such as biodegradable materials, smart packaging (e.g., QR code integration), and AI-driven optimization are being incorporated into next-generation machines. By investing in R&D, we aim to deliver solutions that not only meet current demands but also anticipate future challenges.

In an era where efficiency and reliability define industrial success, the cement bag making machine remains an indispensable asset. Yideng Machinery’s expertise in engineering high-performance, adaptable equipment positions us as a trusted partner for businesses seeking to elevate their packaging operations. Whether you’re expanding production capacity or transitioning to eco-friendly materials, our solutions are engineered to deliver measurable results. Explore our portfolio today and discover how Yideng Machinery can transform your packaging workflow into a competitive advantage.