Innovations in Industrial Paper Bag Manufacturing Equipment: Key Features and Benefits

Release time:2025-05-09 Classification:Knowledge

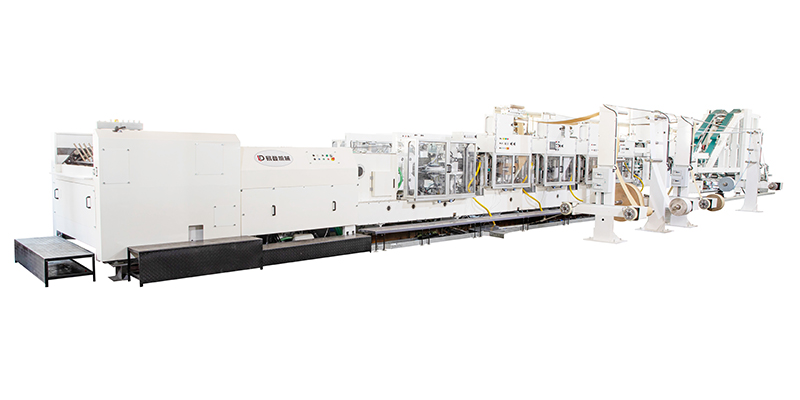

The production of industrial paper bags has evolved significantly, driven by advancements in manufacturing technology. Industrial paper bag manufacturing equipment lies at the heart of this transformation, enabling high-volume production, precision, and sustainability. This article explores the critical components, functionalities, and advantages of modern machinery used in this sector.

Core Components of Industrial Paper Bag Manufacturing Equipment

- Automated Forming Systems: These systems handle the initial stages of bag creation, including paper feeding, folding, and gluing. Advanced servo-driven mechanisms ensure consistent dimensions and minimize material waste.

- High-Speed Printing Units: Integrated printing modules apply logos, safety labels, or branding directly during production. UV-curable inks and precision registration systems guarantee sharp, smudge-free results.

- Bottom Sealing and Reinforcement Units: Specialized stations reinforce bag bottoms using heat-sealing or stitching techniques, ensuring durability for heavy-duty applications like cement or agricultural products.

- Handles and Gusset Attachments: For bags requiring handles or expandable sides, automated units attach twisted, flat, or ribbon handles while forming gussets for added capacity.

- Quality Control Sensors: Optical sensors and real-time monitoring systems detect defects such as misaligned seams or printing errors, reducing rejection rates.

Technological Advancements

Modern industrial paper bag manufacturing equipment incorporates IoT-enabled predictive maintenance, minimizing downtime by alerting operators to potential mechanical issues. Energy-efficient motors and reduced heat emissions align with sustainability goals, while modular designs allow customization for diverse bag sizes and materials, including recycled or biodegradable paper.

Benefits for Manufacturers

- Scalability: High-speed systems produce thousands of bags per hour, meeting demands across industries like food, chemicals, and construction.

- Cost Efficiency: Precision engineering reduces raw material waste and labor costs.

- Sustainability: Equipment optimized for eco-friendly materials supports circular economy initiatives.

Future Trends

Emerging technologies like AI-driven process optimization and robotics are poised to further enhance speed and accuracy. Additionally, hybrid systems capable of handling multi-layer laminated papers will cater to niche markets requiring moisture-resistant or reinforced bags.

In conclusion, industrial paper bag manufacturing equipment is a cornerstone of efficient, sustainable packaging solutions. By leveraging cutting-edge technology, manufacturers can deliver robust, customizable products while adhering to environmental standards and operational efficiency.