What is a Paper Sack Bottomer? Key Features and Benefits for Modern Packaging

Release time:2025-04-27 Classification:Knowledge

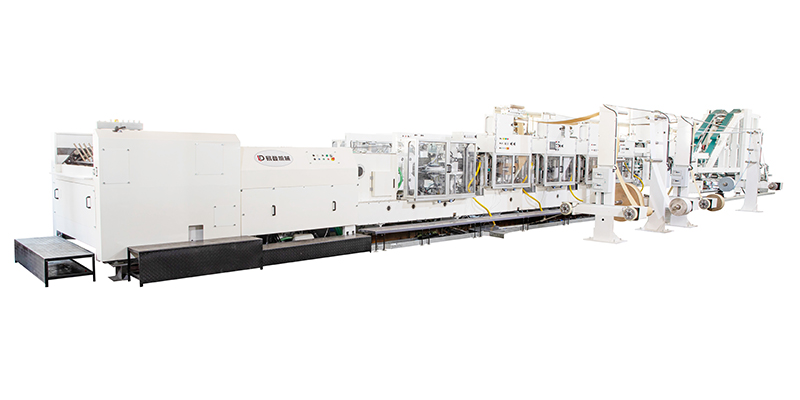

A paper sack bottomer is an essential piece of equipment in industrial packaging, designed to automate and optimize the process of forming, sealing, and reinforcing the bottom of paper sacks. Widely used in industries such as agriculture, construction, food, and chemicals, this machine ensures consistent, high-quality packaging while enhancing production efficiency. Below, we explore its functionality, components, and advantages.

How Does a Paper Sack Bottomer Work?

The paper sack bottomer operates by receiving pre-formed paper tubes and executing a series of precision steps:

- Tube Feeding: Paper tubes are fed into the machine automatically or manually.

- Bottom Formation: The machine folds and shapes the bottom of the sack using forming plates or shoulders.

- Adhesive Application: A specialized adhesive system applies glue to secure the folded layers.

- Pressing & Drying: Pressure rollers ensure a tight bond, followed by a brief drying phase for structural integrity.

- Output: Finished sacks are discharged for filling or further processing.

Key Components of a Paper Sack Bottomer

- Forming Unit: Precision-engineered to create uniform folds.

- Gluing System: Ensures accurate adhesive placement for leak-proof seals.

- Control Panel: User-friendly interface for adjusting speed, glue quantity, and sack dimensions.

- Conveyor System: Transports sacks seamlessly between stages.

Advantages of Using a Paper Sack Bottomer

- Enhanced Productivity: Processes hundreds of sacks per hour, reducing reliance on manual labor.

- Consistent Quality: Eliminates human error, ensuring uniform bottom seals for secure transportation.

- Versatility: Compatible with various sack sizes, weights, and paper grades.

- Cost Efficiency: Lowers material waste and operational costs through optimized adhesive usage.

- Durability: Reinforced bottoms prevent tearing, ideal for heavy-duty applications like cement or fertilizers.

Industries That Benefit from Paper Sack Bottomers

- Agriculture: Packaging seeds, animal feed, or fertilizers.

- Construction: Handling cement, sand, or dry mixes.

- Food & Beverage: Packaging flour, sugar, or powdered ingredients.

- Chemicals: Safely sealing industrial powders or granules.

Sustainability Considerations

Paper sack bottomers align with eco-friendly practices by supporting recyclable and biodegradable paper packaging. Their precision reduces material waste, contributing to greener supply chains.

Conclusion

A paper sack bottomer is a critical investment for businesses seeking to streamline packaging operations, improve product safety, and meet sustainability goals. By automating bottom-forming processes, it delivers reliability, scalability, and cost savings—making it indispensable in modern industrial packaging.