In the dynamic world of industrial packaging, efficiency, precision, and reliability are paramount. The Valve Paper Bag Bottomer Machine stands as a testament to innovation in this sector, offering a specialized solution for sealing and forming the bottoms of paper bags. Designed to meet the demands of high-speed production environments, this machine has become a cornerstone for manufacturers seeking to optimize their packaging processes. This article explores the features, functionalities, and benefits of the Valve Paper Bag Bottomer Machine.

What is a Paper Bag Bottomer Machine?

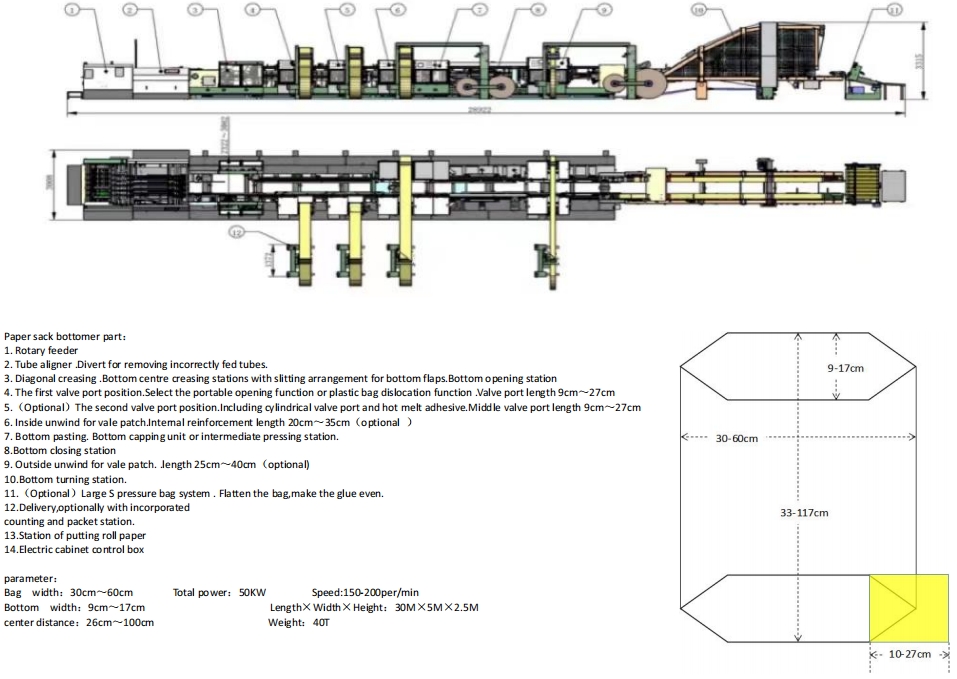

A paper bag bottomer machine is a specialized piece of equipment used to fold, seal, and secure the bottom of paper bags, ensuring structural integrity and durability. This step is critical in the manufacturing process, as a well-sealed bottom prevents leaks, maintains bag shape, and ensures the safe transport of goods. The Valve Paper Bag Bottomer Machine excels in this role, combining mechanical precision with advanced automation to deliver consistent results.

Key Features of the Valve Paper Bag Bottomer Machine

- High-Speed Operation

The machine is engineered for rapid production, capable of processing hundreds of bags per minute. This speed is ideal for large-scale operations, reducing bottlenecks and maximizing throughput. - Versatility in Bag Sizes

The machine accommodates a wide range of bag dimensions and paper types, from small retail bags to heavy-duty industrial sacks. Adjustable settings allow quick transitions between different product specifications, minimizing downtime. - Precision Folding and Sealing

Utilizing advanced servo-driven mechanisms, the Valve Bottomer ensures accurate folding and sealing of bag bottoms. This precision eliminates weak spots, enhancing the bag’s load-bearing capacity. - Adhesive Application System

The machine employs a controlled adhesive dispensing system, applying the exact amount of glue required for a secure bond. This reduces waste and ensures a clean, professional finish. - User-Friendly Interface

An intuitive touchscreen control panel allows operators to monitor performance, adjust parameters, and troubleshoot issues in real time. Automated diagnostics further streamline maintenance. - Durability and Low Maintenance

Constructed from high-grade materials, the machine is built to withstand continuous operation in demanding environments. Its modular design simplifies part replacement and upkeep.

Applications

The Valve Paper Bag Bottomer Machine is widely used across industries, including:

- Food Packaging: For flour, sugar, grains, and other dry goods.

- Retail: Creating sturdy shopping bags and branded merchandise carriers.

- Industrial: Producing heavy-duty sacks for cement, chemicals, or construction materials.

- E-commerce: Ensuring secure packaging for delivery.

Advantages Over Traditional Methods

- Consistency: Eliminates human error in folding and gluing.

- Cost Efficiency: Reduces labor costs and material waste.

- Scalability: Supports high-volume production without compromising quality.

- Sustainability: Optimizes adhesive use and supports recyclable paper materials.

Innovation at Its Core

Valve’s engineering team has integrated smart technologies into the machine, such as IoT connectivity for predictive maintenance and data-driven performance analytics. These innovations empower manufacturers to align with Industry 4.0 standards.

Conclusion

The Valve Paper Bag Bottomer Machine represents a leap forward in packaging automation. By delivering speed, precision, and adaptability, it addresses the evolving needs of modern manufacturers. As industries increasingly prioritize sustainability and operational efficiency, this machine emerges as a vital tool for businesses aiming to stay competitive in a fast-paced market. Whether for food, retail, or industrial applications, the Valve Bottomer Machine sets a new benchmark in paper bag production excellence.